Intro to Taking Bar Inventory

Taking bar inventory can sometimes feel like the boogeyman waiting at the end of the month. Most bartenders and managers tasked with inventory dread it. Now imagine those bottles are made of dollars.

Doesn't seem so dreadful now, does it?

Bottles sitting in your storage area are just bottles of unusable cash and counting them is just the beginning.

Perpetual Inventory vs. Physical Inventory

Before we get into how to take bar inventory, let's go over two types of inventory methods, perpetual and physical.

Using point-of-sale to track perpetual inventory

Perpetual inventory is counting down your inventory as it sells (and adding to it when you buy) so that you always know your current inventory on-hand. Keeping a perpetual inventory makes placing weekly liquor orders much easier, and can also assist in 86'ing items from your menu so a customer doesn't order something you're out of.

However, perpetual inventory is a theoretical value and is highly dependent on the accuracy of input to your POS system and other variance. You can automate perpetual inventory with point-of-sale integration for Backbar.

Consistency is key for physical inventory

Physical inventory is the act of actually counting each of your items. It is certainly more accurate than perpetual inventory, but requires a lot of labor and is not performed frequently, making it unreliable for placing weekly orders.

The most effective means of inventory management is using the combination of perpetual inventory and physical inventory.

Inventory variance shines a spotlight on missing inventory

If perpetual inventory is your theoretical expected value, and your physical inventory is your actual value at a given point in time, then your variance is the difference between the two. And when you perform your physical inventory, you reconcile the perpetual inventory count so that the number resets to the actual number counted.

Manually tracking inventory variance is more difficult and cumbersome. You will need a spreadsheet to track the starting and ending inventories, all items purchased, the costs and sales of each item. Unless you prefer to spend hours each day doing data entry into spreadsheets instead of being on the floor, for many bars and restaurants it is not feasible to do accurately without software.

Opening and Closing Inventory (Or Beginning and Ending Inventory)

Backbar offers a free bar inventory template to help you get started

The restaurant industry standard is to take inventory on the last day of each month.

This means that your inventory periods and data will be in monthly segments.

It's important to stay consistent with when you take inventory because it will standardize the period of information you use to calculate your beverage program's performance.

When calculating things like Inventory Usage Rate, you have three factors:

- Opening (or starting) Inventory

- Goods Purchased

- Closing (or ending) Inventory

If you are taking your inventory counts for the month of February, and you conducted January inventory on the 31st, then you can use the January closing inventory as your opening inventory for February.

Throughout the month, record your weekly purchases in a separate column or spreadsheet tab so you can identify your new purchases from the previous standing inventory.

Finally, take your closing inventory on the last day of February.

From there, you can use those three data points to calculate important things like usage rate and identify sales trends.

Time of Day

Take inventory while your restaurant or bar is closed. This may require you to come in earlier if you're business doesn't serve breakfast or lunch hours. It may also mean staying late after a shift. Or, if your venue isn't open 7-days a week, then coming in on the off day will provide you plenty of time (and peace) to record inventory.

Weekly Inventory for Purchasing

Each week you will be placing purchase orders with your vendors. It's important to track inventory closely so you don't order and spend too much. Keeping a perpetual inventory, where possible, helps tremendously with more quickly determining weekly orders.

Over-ordering will cause your pour costs to bloat and will suck up profits by having too much money tied up in standing inventory. Under-ordering will cause you to disappoint customers by running out of items and will also put stress on your staff.

Setting Par Levels Helps Control Inventory Levels

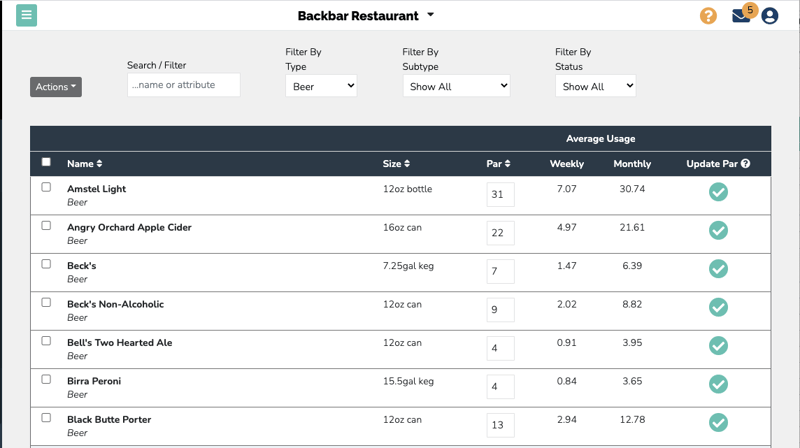

Backbar's par level manager suggests par levels based on product usage

A par level is the quantity or amount of an item that should be kept in stock to meet demand.

Identifying par levels for your popular items will help you know how often to order product and when you can skip ordering it. In Backbar, our software can suggest par levels based on product usage rate. We use the monthly usage rate to determine par levels so bar operators can limit orders of items to once-per-month if possible.

Recording Daily Inventory Updates

Some bars will record daily inventory updates to keep a keen eye on their product usage. For things like bottles of beer and wine, this is easily done by generating a sales report from the POS system.

For things like spirits or wine by-the-glass, you can manually record when a bottle is finished, called "bottle kills," or if your service and bar space allows, physically save the bottles to count at the end of the night and create a "kill list" from these bottles.

How to Take Inventory Counts

Train Yourself and Staff

Consistency is key for taking inventory counts. Especially when it comes to open, or partial bottles. If you're taking inventory counts by eye, then you will need to make sure you are consistent and to also train your staff to assess bottle volume with accuracy and consistency. The difference between considering a bottle to be .75 full and .8 full is negligible, but it's important to call a .8 a .8 each time you see it.

Bar Inventory Apps & Other Methods

There are many different systems and methods for taking your bar inventory and everyone has different preferences. The best systems will provide the most value to your business at a competitive cost.

Important considerations for liquor inventory apps:

- Ease of use

- Speed

- Compatibility with other management tools or technology

- Onboard process

- Hardware

- Reporting and data provided

- Auxiliary services like distributor ordering

Different Inventory Methods

Pen and Paper

If you own a bar on a beach, and the bar is just a hut with a roof thatched from dried grass, and the beach is on a volcanic island that dots the Pacific Ocean, then taking inventory with a pen and paper is probably fine. If you're not that exact bar then you need a better way to take inventory.

Pen and paper inventory is the least valuable form of beverage inventory. It's disorganized, labor intensive, and does not provide any valuable data or insights into your business.

Spreadsheets for Inventory (Excel)

This is the most common method for recording and taking inventory because if you have a computer then you have access to a spreadsheet tool. But spreadsheets are cumbersome and take a lot of time and expertise to manage.

Pros:

- Accessible

- Familiarity

- Can customize and create formulas to calculate data

Cons:

- Labor intensive

- Difficult to generate data

- Not compatible with other software or hardware

- Data not usually accessible from other devices

The Differences Between Bar Inventory Software

A quick google search will reveal that there are many inventory software services available for restaurants and bars. These platforms are generally focused on providing a simple interface for taking inventory counts and providing reports and and inventory analysis.

Here's a sample overview of Backbar one of the top bar inventory solutions available.

Pros:

Pros:

- Time saving counting interface

- Easy set up

- Mobile-friendly and can use on any device

- Multiple people can count simultaneously

- Dozens of pre-built reports

- Distributor ordering platform

- Digital menu compatible

- Upload invoices to auto-record costs

- Export all data and reports to spreadsheets

Cons:

- POS integration not available for all systems

- Must identify bottle volume by sight for physical inventory

- More expensive than spreadsheets (but still very affordable)

Barcode Scanners for Inventory

Another system for taking inventory is a barcode scanner. The scanner is used to identify the items in front of you to enter in the relevant inventory information.

Pros:

- No need to manually search items

- Faster than spreadsheets

Cons:

- Not all items on-premise have barcodes

- Generally must print out custom labels for bottles without barcodes

- Lag on scanning technology in some cases

- Problems with accurately identifying items

- Must purchase and maintain additional scanner hardware

- Limits number of people who can do inventory simultaneously to the number of scanners

Weight Scales

Measuring bottles of inventory by weight can offer very accurate inventory counts. But a small weight difference isn't the most important aspect of taking inventory. And splitting hairs on liquid volume doesn't provide the insights into inventory necessary to increase profits.

Pros

- Accuracy

Cons

- Hardware costs

- Multi-step process that requires you to weigh bottle and then record weight

- Time consuming

Creating a Bar Inventory Template

Organization is essential for an efficient inventory system that adds value (dollars) to your business. Staying organized will also save you significant time and reduce the frustrations of performing inventory.

Inventory Locations

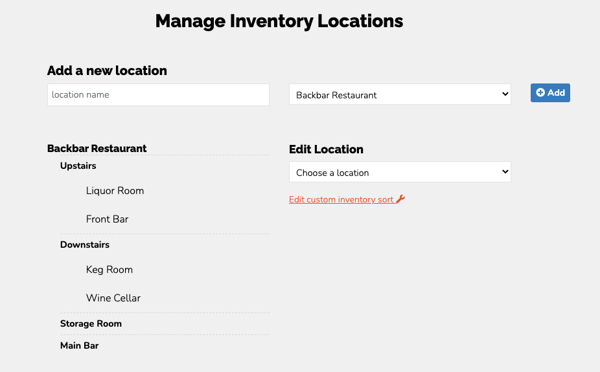

Whether you use a spreadsheet or an inventory solution like Backbar you should set up separate locations or areas for your items. Locations are the physical places that inventory is stored in your restaurant or bar.

Backbar allows you to set up and take inventory on different locations to get a better view of inventory performance across your venue

This will help you maintain accurate counts and keep things streamlined when you're taking inventory. It also allows you to divide up the work of counting inventory at the end of the month more easily by having different staff counting in different areas at the same time. You can total the counts for each item in each location when you've completed counts for all locations.

Item Order for Inventory List

Once you've established your inventory locations, it's time to add and organize the products listed in each section. The best way to do so is not necessarily alphabetically, but by matching the order of your inventory list to the order in which they are physically organized behind the bar and in storage. This allows you to quickly go down your list as you come across the actual bottles to record counts.

Recording Costs

In order to calculate important information like Pour Costs, Variance, and Margins, you need to know the cost of each product you've purchased.

To record your costs, you will have to copy pricing information from your invoices into a spreadsheet. If you're using Backbar, you can upload your invoices to our system to have your costs recorded for you automatically.

The most important information is the cost per bottle. So if you order cases, divide the case price (including discounts and taxes if possible) by the number of bottles in the case to find the bottle cost. It's best to keep as much information centralized as possible.

So if you use a spreadsheet for inventory, you should add a separate column for item cost.

Establish Pour Sizes and Pricing

Your pour sizes and pricing for products like wine and spirits will be influenced by your costs.

A general guideline for pricing is to sell items at a 20% liquor cost. That is, if an item costs you $1, you would sell it for $5. So, 1/5 =.2 or 20%.

Standard wine pours are typically 5 oz. or 6 oz. per glass

Standard pours for spirits are 1 - 2 oz. for neat pours, or 1.5 to 2 oz. for mixed drinks

20% isn't always possible with premium items like a rare whiskey or an expensive bottle of wine because you may price out your customers by charging too much to hit a 20% pour cost. It's important to know your client base when setting prices. In general, the lower the cost of an item, the higher the pour cost should be; and the more expensive the cost of an item, the lower the pour cost should be.

Your cheapest wines by the glass may have a pour cost of 25%, while your most expensive wines by the bottle may have a pour cost of 60%. Despite a much higher pour cost, you'd prefer to sell a $200 bottle of wine with a 60% pour cost ($80 of gross profit) compared to a $50 bottle of wine with a 30% pour cost ($35 of gross profit).

Establishing the liquor cost percentage is easy once you know the cost per bottle. For spirits, wine, beer and other liquors sold by the ounce (as opposed to selling by the bottle), you will need to calculate the cost per ounce. Record your sale price for each item in a column next to your cost column.

To calculate cost per ounce, divide the bottle cost by the number of ounces.

Identifying the cost per ounce will also help you decide on your pour sizes by determining the margin you want per bottle for items sold by the ounce.

For wine, where a standard bottle is 750ml or 25.3 ounces, industry standard is 5 oz. pours (yields 5 glasses per bottle) or 6 oz. (4 glasses per bottle).

Planning Ahead

One of the points we've hammered on in this inventory guide is that inventory is about much more than just counting bottles. The information you capture from a mature inventory system can be the difference between failure and success for your business. And although we've thrown at you a lot of complex formulas and calculations, running an efficient and profitable inventory system is not as difficult as it seems, it just requires some upfront planning.

When putting together your liquor inventory spreadsheet you will want to decide what type of information you want to have available for analyzing your bar program.

For example, if you want to know how much money you have tied up in wines vs. beer, then you will need to add a spreadsheet column to notate the type of beverage it is. Backbar and other inventory programs are so useful because that information is already associated with the items you enter into the system.

Here are some categories you may want to capture information on for inventory analysis:

Product Types

Wine, Beer, Spirits, etc.

Subtypes

Red wine, White wine, IPAs, Lagers, Tequila, Vodka, Whiskey, etc.

Vendors

The distributors you purchase from alcohol and beverages from.

Size

Determines pour costs, pour sizes, price point

Varietal or Style

Chardonnay, Merlot, Single Malt Scotch, Blended Scotch, Blanco Tequila, Anejo Tequila

Why this information is useful

Capturing data by additional categories like those listed above will help you determine which areas of your business are most profitable. It will also help ensure you don't have too much money tied up in inventory of any specific type of product.

For example, if Cabernet Sauvignon accounts for 15% of your wine sales, it would be useful to know if your on-hand inventory value of Cabernet deviated drastically from 15%.

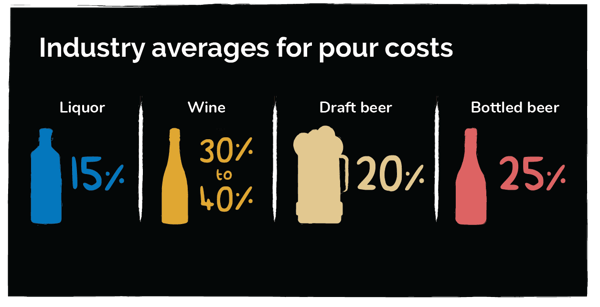

We noted above that different types of alcohol have different average pour costs. By capturing more data to analyze your beverage program you can approach your inventory data from different perspectives to determine how you can become most successful.

Liquor Cost Formulas

Taking inventory is like a physical exam that checks up on your bar's financial health. Understanding where and how much money is tied up in your inventory is the first step to achieving goals like lowering your pour costs and driving profits from your beverage program.

To understand your bar program's finances, you'll need to be familiar with a few bar inventory terms and formulas.

Liquor Cost Formula

Liquor costs, or pour costs are the ratio between the cost of products purchased and the revenue from products sold.

Product Costs / Product Sales = Liquor Cost

Your pour cost is important because if it is too high, then you will generate lower profits overall from beverage sales. Liquor costs have an inverse relationship to margin.

Another way to state margin, is that for every extra dollar in sales you make, the margin is the incremental gross profit (profit before other expenses such as fixed costs, labor, utilities, etc...).

Your margin percentage is calculated as:

(Sales - Costs) / Sales = Margin

Looking at industry costs is a good guideline, but depending on your business, you will want to determine the ideal pour costs and margins for you. A business in a major metropolitan city with high rents and labor costs will need lower pour costs and higher margins than one that isn't.

Here are industry averages for pour costs:

Cost of Goods Sold

Cost of Goods Sold (COGS) is the direct costs required to serve your drinks and make sales. This includes the cost of everything going into and necessary for creating the drinks along with the direct labor costs used to produce the drinks.

For example, this includes supplies such as the liquor, garnishes, juices, mixers, soda, and napkins, and labor such as the bartender, barback, server and dishwasher, who all may be required for you to sell a drink to a customer. For individual drinks you may wish to just use the liquor cost as an approximation of the COGS, but for your entire bar financial picture all other direct costs should be included.

Inventory Variance

Variance, or shrinkage, is inventory product that is gone but not accounted for by sales. The missing inventory could be a product of over pouring drinks, unaccounted breakage, or even something as concerning as theft.

It's not possible to fully eliminate variance, but it is possible to reduce variance which will increase profits.

Here is the basic inventory variance formula:

Ending Inventory Count - Initial Inventory Count + Purchases - Sales = Variance

You can think of the above formula another way: your actual inventory count minus expected inventory count. In the formula above, you expect your count to be what you initially had plus the quantity you bought minus the quantity you sold.

Setting Par Levels

Inventory Turnover Helps You Spend Money Wisely

Another critical metric to measure is inventory turnover. Inventory turnover is important to know because it tells how well you are using your cash, how often you need to order items and what your item par levels should be.

Inventory turnover is a ratio showing how many times you have sold and replaced inventory during a period. You can then divide the days in the period by the inventory turnover formula to calculate the days it takes to sell the inventory on hand. The higher the turnover the better (you are using cash more efficiently to generate sales).

The formula for inventory turnover is:

Cost of Goods Sold / Average Inventory= Inventory Turnover

To calculate average inventory for the formula above, use:

(Beginning Inventory + Ending Inventory) / 2 = Average Inventory

And then to determine the days it takes to sell inventory, use the formula:

Days [between beginning and ending inventory] / Inventory Turnover = Average Inventory

Example

At the beginning of month 1 you count $50,000 in inventory. At the end of month 3 you count $90,000 in inventory. Your average monthly inventory is ($50,000 + $90,000) / 2 = $70,000.

If your cost of goods sold during that period is $140,000, your inventory turnover is 2. If you divide the number of days in the period (90) by your turnover (2), you'll find out that you sell through your inventory every 45 days.

Liquor Inventory Usage Rate

Inventory usage is the pace at which inventory is depleted. It is an alternative look at sales by measuring the quantity of items sold instead of the revenue itself.

Here is the inventory usage formula to calculate your usage rate.

Opening Inventory + Purchases Received - Closing Inventory = Inventory Usage

Par Levels Make Life Easier

Establishing par levels will give you a guideline for the minimum amount of a product that you should have on hand at all times. Setting par levels will help you put together liquor orders with your distributors. It accomplishes two important things:

(1) not tying up excessive cash in inventory, and (2) making sure you don't run out of products.

We can use the formulas from the previous section to determine par values. Calculate the inventory turnover ratio for each item, then calculate the number of days to sell the inventory.

Most liquor orders are placed weekly, so you should at least plan on having enough product for 7 days. You should also add a safety factor to account for sales fluctuations, or if there's difficulty sourcing the product consistently. We recommend a safety factor between 1.5x - 3x depending on the product and supplier.

Example

Monthly Inventory Turnover = 10

Days to sell inventory = 3

Number of products sold per week = 2.33

Occasionally the distributor is out of stock of this item, so we'll add a safety factor of 2.5

Par Value = 2.33 x 2 = 5.8

Biggest Bar Inventory Mistakes

Too many bars and restaurants don't take inventory seriously. This leaves owners and operators in the dark in terms of how their bar program is performing, and how they can improve operations.

Not Conducting Regular Inventory

Some restaurants don't even conduct inventory, or only do it several times a year. That is the biggest mistake a venue can make. It's important to understand the health of your inventory in order to establish a successful beverage program.

Bad Ordering Habits

Businesses get in trouble when they aren't disciplined with their purchasing. They end up with an ever-growing array of different products, often times sitting in storage and never even making it to the bar.

It may be they wanted to offer the newest flavored whiskey, or someone personally liked a new wine so they decided to buy it, and these types of purchasing habits cascade over time, until you have far more inventory than necessary.

Not Tracking Pour Costs and Analyzing Data

As illustrated in this guide, inventory is about much more than counting bottles. It's necessary to measure and analyze beverage data to make informed decisions. The most successful restaurateurs in the world are very data-driven to maximize profits in an industry with slim margins

Bar Inventory Checklist

Let's recap what we've discussed above.

We know that taking inventory is crucial for successful restaurants and bars. And that the data you track and record will help you run a more efficient business, and give you the information needed to make confident decisions. Let's recap what we've discussed above.

Inventory Checklist

What to monitor and look for

Inventory Value

Track the total value you have in inventory and work to reduce that number

Inventory Usage Rate

Identify how often you are pouring through products to determine order frequency and sales behavior

Determine Liquor Costs

Work to lower your pour costs to generate higher profits

Identify Variance

Track perpetual inventory and variance to reduce lost profits

Understand Sales Trends

Understand your business and what your customers are likely to purchase at your venue

Business Trends

Track seasonal habits, the impact that events have on sales, and overall industry trends that you can capitalize on

How to optimize your beverage program

Maintain a consistent inventory system

Generate important data, record purchases, track sales

Sell down overstock inventory

Put items on special, utilize product in cocktails and the kitchen, engineer your menu, establish loss leaders

Set item pars

Determine how much of each item you need in stock to satisfy customer demand

Construct and adhere to a purchasing budget

Build a budget with a goal to reduce your inventory totals and leverage distributors for better pricing.